Duratec / Mazda L-Series MZR I4 2.0 / 2.3 / 2.5 Swap

- DPDISXR4Ti

- Site Admin

- Posts: 14831

- Joined: Wed Jan 08, 2003 11:40 pm

- Location: New York

Re: Duratec / Mazda L-Series MZR I4 2.5 Swap

This is a long and very detailed post regarding the Duratec/Mazda L-series engine. The original source went away so I'm just cut and pasting it in here for reference....

It was agreed many years ago, that Mazda would drop their (class leading) K-series V6, hand over the engineering to Ford and Ford would continue to develop 60 degree aluminum V6's as their Duratec V6, which Mazda would have later access to to cast, build and modify to their liking. In exchange, Mazda would be responsible for the entire development of the "new four cylinder engines". This is the deal according to Ford. Mazda would be developing a new 4 cylinder engine, regardless. Selling the K-engine out, made and saved them some money. The company has always had some of the best engineering in Japan, but sadly most of it falls short of production (including V8 and V12 engines). Ford always knew this, which is why they hooked up with the company since the 70s.

"MZR" is just a brand name, just like 'Duratec' (and EcoBoost for that matter). It means nothing. The Mazda L-engine is the engine family in question, and is all 100% Mazda engineering. The L-engine, is part of the MZR series (which is a brand name for a generation of engines, including the smaller Z-engines as well). The L-engines range in size from 1.8L to 2.5L.

Quick primer on understanding engine codes (useful for the rest of the post):As mentioned before, MZR and Duratec are brand names, for a generation of engines. They in no way specify an engine, or even an engine family. The 1.8L to 2.5L MZR's we know so much are of the L-family of engines.

L8 is the 1.8L engine code. "P" and "8" have always been used to represent an "8" in a Mazda 1.8L engine ie. (BP 1.8L, F8 1.8L, FP 1.8L, K8 1.8L V6).

LF is the 2.0L engine code. L is a family letter, and F is the displacement varient. F in this case is in reference to the 2.0L FE, which this engine was designed off of. 2.0L (E also used to represent an even liter displacement ie. JE for 3.0L J-family V6, no longer used).

L3 is the 2.3L engine code. 3 and J have been used to represent x.3L engines (ie. KJ 2.3L V6, B3 1.3L etc)

L5 is the 2.5L engine code. 5 and L have been used to represent x.5L engines (ie. J5 2.5L V6, KL 2.5L V6)

The suffix describes the engine configuration/features

L3-DE would be the 2.3L as used in the Ford Ranger.

L3-VDT would be the 2.3L DISI turbo

The first suffix position may be either:

D= Domestic DOHC or

Z= High Tuned DOHC

V= VVT DOHC or

C= Common Rail Diesel

Second place suffix position may be either:

E=EFI

D=Direct Injection

Third place suffix position is optional:

T= turbo

M= Miller Cycle

So the 2.3L Supercharged Miller Cycle V6 would have a KJ-ZEM engine code.

2.3L DISI Turbo engine would have L3-VDT code.

2.2L MZR-CD diesel would have R2-CDT code.

2.3L in Ford Ranger would have a L3-DE Mazda code.

2.3L VVT would have L3-VE code.

So here's the story:

L-engines (or all engines of the same family) are all identical on the outside, more or less, with bolt bosses, head patterns and bell patterns being identical between them ALL (same block, diff internal machining for disp). L-engine is an evolution of the Mazda F-engine (circa 1983-1998) which ranged in size from 1.6L to 2.2L). In fact, the old iron F-engine block is still being used to this day as Mazda's diesel R-engine (2.2L sharing the exact same bore/stroke/rod length as the F2 2.2L, same block).

Yes, the same block has been doing double duty as petrol F- and diesel R- since 1983! tig1, if you read this, that means that your old 2.0L Diesel Tempo's engine block is still in production today! And was the basis for the L-engine/Duratec 4cyl!

The R-engine "MZR-CD" 2.2L is one of the best 4 cylinder diesels currently on the market. Even the Germans know this (VW admitted it somewhere). But back on topic though, the ubiquitous L3-VE/VDT/DE 2.3L carries the exact same stroke length of the old F2 2.2L, nearly identical bore spacing, and an almost identical rod length (yeilding nearly identical rod ratio, one the highest in it's class @1.64~).

Changes and inevitable updates from the old F-engine to new L-engine include:*all aluminum block construction vs cast iron

*1 piece main bearing cage vs caps with girdles and braceplate

*reversed intake/exhaust flow config, as has become industry standard

*belt to chain driven cams (after going from chain to belt during the belt fad of the 80s)

*no more SOHC. The DOHC heads combine engineering from the Mazda KL V6 DOHC heads (27degree valve angle), and the older DOHC FE3 2.0L engine (or B-engine DOHC heads which are just mini versions)

*VVT system identical to S-VT ZL 1.5L) All heads use flat bucket tappets.

*chain driven oil pump (instead of direct crank driven oil pump mounted to crank snout)

*weight reduction of recip. mass

-3mm smaller rod journal diam. over the old overbuilt F-engine, however 2.3L DISI turbo and 2.5L n/a engines retain original rod journal size of F-engine

-much shorter piston compression height (down -5mm!), semi skirted race style pistons, much skinnier rods (the old F-engine rods were good for well over 4 times their original HP, but were needlessly heavy for regular use)

-crank gear driven twin balance shafts for 2.3L and 2.5L

-plastic intake manifolds with continued use of VICS, adding VTCS; weight reduction

Note: you'll find many of these are common changes between many manufacturers like Toyota from their S-engine to their AZ-engine for example.

The engine is offered in different configurations for a needed displacement. Before the 2.5L L5-VE engine, there were only 2 cranks used on L-engine, now there are three.

L-engine crank and bore combinations:83mm stroke (for 2.0 & 1.8L - replaces 77mm crank from F-engine)

94mm stroke (unchanged from 2.2L F-engine)

100mm stroke (new for 2.5L L5)

Standard bore for the L-engine is now 87.5mm, instead of 86mm from F-engine. For the smallest 1.8L, the same 83mm crank as the 2.0L is used, but bore reduced to 83mm as well (square 83x83mm). The 1.8L "MZR" is used overseas for Mazda6, 3 and Ford "Duratec HE".

For comparison, the F-engine had 3 cranks, and 2 bore sizes 86mm being standard bore, however the smaller bore size (83mm) was the rarest:

77mm stroke (86x77mm for 1.8L, 83x77mm for the rare 1.6L)

86mm stroke (86x86mm FE 2.0 was square )

94mm stroke (used for 2.2L F2 and carried over to the L-engine)

So now with a little bit of history, in the early 2000's it was published that Ford had indeed trusted Mazda for a new global 4cylinder for Ford to use. (Mazda's own engines have always been their "global" engine, so no need to change anything on their end). Ford attempted a DOHC 4 cylinder with their ZETEC, being loosely based on Mazda's 1.8L BP, but that engine was short lived. The F-engine was produced from 1983 to the mid-late 90's, where Mazda replaced it with an odd FS/FP 2.0L/1.8L for the Protege generation (was more like a stretched out BP, than close to anything of the real F-engine family). That engine was produced for about ~5yrs, before they went back to a large bore spacing engine like the L- & F-.

"But there are parts on the Mazda and Ford engines that says FoMoCo on it, so you're lying"

Indeed there are, but I'm not even close to lying. This is where the OEM agreements take place. Mazda accepted Ford's offer of helping them save some money on the bread and butter parts like plugs, throttle bodies, dipsticks- you know the [censored] little costs on the little knick knack details. Ford offered these everso discreetly labelled items, you know, as part of an exchange for being able to cast a Mazda engine and use it in over half of their entire lineup. That seems a little more than fair. But, Ford also knows the psychology value in that as well. But I digress.

Now, I realise this is far more info than anyone could have cared for, but I think the story is very good start to at least know the heritage. There is far too much speculation and rough estimates out there, even from journalists in internetsworld that people are stating as fact.

Nick, you've got a good engine. If you have a sensor sticking out of the valve cover on the chain side, you've for VVT. Oh, and you've got nothing to worry about!

--- I would also add Ford opted to drop the Mazda's VVT in favor of there own to be released later (when?) varible valve timming.

-- also mazda use 3wire coil on plug (ignitors built in? I hope) compared to 2wire COP's (seperate ignitor needed).

The new Ford Duratec 2.3L (23E) engine generates 144 horsepower - 10 percent more than today's 2.0-liter Zetec engine - with SULEV emissions. It is due to be upgraded with even more power to 150 horsepower for the 2005 model year, but will lose the PZEV emissions equipment. The PZEV engine will be downsize to a 2.0L displacement.

The new engine is standard equipment in five states and will be available in all the other states, but is reported not to be available in Canada.

Clean, fuel-efficient engine is a product of Ford's "revolution under the hood" that will see more than 1.5 million engines built around the globe from the same in-line four-cylinder (I-4) architecture.

Ford's new Duratec 23E engine, first introduced in the 2003œ Ford Focus PZEV (Partial Zero Emissions Vehicle) in California, New York and Massachusetts and now available nationwide, is both powerful - producing 151 horsepower at 5,750 rpm and 154 pounds-feet of torque at 4,250 rpm - and exceptionally clean.The engine helps Focus meet California's Super Ultra-low Emissions Vehicle (SULEV) standard, which allows vehicles to emit only one pound of smog-forming pollution over 15,000 miles of driving. That's good enough to earn the car a perfect "10" on the U.S. Environmental Protection Agency's Guide to Green Cars. The car also has zero fuel system evaporative emissions. EPA estimated fuel economy is 25 mpg city and 33 mpg highway with the standard five-speed manual transmission and 24 mpg city and 30 mpg highway with the optional four-speed automatic.

"The Focus PZEV and the Duratec 23E are technological breakthroughs that deliver real-world environmental benefits without asking consumers to make a single compromise in performance, driving range, refinement or practicality," said John Sidelko, Focus chief engineer. All 2.3-liter Focus models in 2004 are identical to the Focus PZEV. They share the same emissions hardware, fuel system components and powertrain calibration. However, the emissions are slightly less clean outside of California because of that state's unique fuel formulations.

Power, Refinement and Low EmissionsThe new engine achieves its impressive level of performance, refinement and low emissions through careful design of the engine block and cylinder heads, air and fuel intake systems, powertrain controls, combustion chambers and exhaust system. The Duratec 23E cylinder block is a precision aluminum casting with a deep skirt that extends well below the crankshaft center line to improve bending stiffness. A separate cast aluminum alloy ladder frame carries the lower bearing shells. This casting is secured by 10 bolts, one on each side of the bearing. Dry, cast-iron cylinder bore liners are cast into the block. A structural ribbed aluminum oil plan and cast alloy front cover further stiffen the block and reduce noise transmission.The extensive use of aluminum components and direct mounting of accessories to the engine block helps to reduce the total installed weight of the engine by 40 pounds, or 12 percent, compared with the Ford 2.0-liter Zetec I-4 engine.

It was agreed many years ago, that Mazda would drop their (class leading) K-series V6, hand over the engineering to Ford and Ford would continue to develop 60 degree aluminum V6's as their Duratec V6, which Mazda would have later access to to cast, build and modify to their liking. In exchange, Mazda would be responsible for the entire development of the "new four cylinder engines". This is the deal according to Ford. Mazda would be developing a new 4 cylinder engine, regardless. Selling the K-engine out, made and saved them some money. The company has always had some of the best engineering in Japan, but sadly most of it falls short of production (including V8 and V12 engines). Ford always knew this, which is why they hooked up with the company since the 70s.

"MZR" is just a brand name, just like 'Duratec' (and EcoBoost for that matter). It means nothing. The Mazda L-engine is the engine family in question, and is all 100% Mazda engineering. The L-engine, is part of the MZR series (which is a brand name for a generation of engines, including the smaller Z-engines as well). The L-engines range in size from 1.8L to 2.5L.

Quick primer on understanding engine codes (useful for the rest of the post):As mentioned before, MZR and Duratec are brand names, for a generation of engines. They in no way specify an engine, or even an engine family. The 1.8L to 2.5L MZR's we know so much are of the L-family of engines.

L8 is the 1.8L engine code. "P" and "8" have always been used to represent an "8" in a Mazda 1.8L engine ie. (BP 1.8L, F8 1.8L, FP 1.8L, K8 1.8L V6).

LF is the 2.0L engine code. L is a family letter, and F is the displacement varient. F in this case is in reference to the 2.0L FE, which this engine was designed off of. 2.0L (E also used to represent an even liter displacement ie. JE for 3.0L J-family V6, no longer used).

L3 is the 2.3L engine code. 3 and J have been used to represent x.3L engines (ie. KJ 2.3L V6, B3 1.3L etc)

L5 is the 2.5L engine code. 5 and L have been used to represent x.5L engines (ie. J5 2.5L V6, KL 2.5L V6)

The suffix describes the engine configuration/features

L3-DE would be the 2.3L as used in the Ford Ranger.

L3-VDT would be the 2.3L DISI turbo

The first suffix position may be either:

D= Domestic DOHC or

Z= High Tuned DOHC

V= VVT DOHC or

C= Common Rail Diesel

Second place suffix position may be either:

E=EFI

D=Direct Injection

Third place suffix position is optional:

T= turbo

M= Miller Cycle

So the 2.3L Supercharged Miller Cycle V6 would have a KJ-ZEM engine code.

2.3L DISI Turbo engine would have L3-VDT code.

2.2L MZR-CD diesel would have R2-CDT code.

2.3L in Ford Ranger would have a L3-DE Mazda code.

2.3L VVT would have L3-VE code.

So here's the story:

L-engines (or all engines of the same family) are all identical on the outside, more or less, with bolt bosses, head patterns and bell patterns being identical between them ALL (same block, diff internal machining for disp). L-engine is an evolution of the Mazda F-engine (circa 1983-1998) which ranged in size from 1.6L to 2.2L). In fact, the old iron F-engine block is still being used to this day as Mazda's diesel R-engine (2.2L sharing the exact same bore/stroke/rod length as the F2 2.2L, same block).

Yes, the same block has been doing double duty as petrol F- and diesel R- since 1983! tig1, if you read this, that means that your old 2.0L Diesel Tempo's engine block is still in production today! And was the basis for the L-engine/Duratec 4cyl!

The R-engine "MZR-CD" 2.2L is one of the best 4 cylinder diesels currently on the market. Even the Germans know this (VW admitted it somewhere). But back on topic though, the ubiquitous L3-VE/VDT/DE 2.3L carries the exact same stroke length of the old F2 2.2L, nearly identical bore spacing, and an almost identical rod length (yeilding nearly identical rod ratio, one the highest in it's class @1.64~).

Changes and inevitable updates from the old F-engine to new L-engine include:*all aluminum block construction vs cast iron

*1 piece main bearing cage vs caps with girdles and braceplate

*reversed intake/exhaust flow config, as has become industry standard

*belt to chain driven cams (after going from chain to belt during the belt fad of the 80s)

*no more SOHC. The DOHC heads combine engineering from the Mazda KL V6 DOHC heads (27degree valve angle), and the older DOHC FE3 2.0L engine (or B-engine DOHC heads which are just mini versions)

*VVT system identical to S-VT ZL 1.5L) All heads use flat bucket tappets.

*chain driven oil pump (instead of direct crank driven oil pump mounted to crank snout)

*weight reduction of recip. mass

-3mm smaller rod journal diam. over the old overbuilt F-engine, however 2.3L DISI turbo and 2.5L n/a engines retain original rod journal size of F-engine

-much shorter piston compression height (down -5mm!), semi skirted race style pistons, much skinnier rods (the old F-engine rods were good for well over 4 times their original HP, but were needlessly heavy for regular use)

-crank gear driven twin balance shafts for 2.3L and 2.5L

-plastic intake manifolds with continued use of VICS, adding VTCS; weight reduction

Note: you'll find many of these are common changes between many manufacturers like Toyota from their S-engine to their AZ-engine for example.

The engine is offered in different configurations for a needed displacement. Before the 2.5L L5-VE engine, there were only 2 cranks used on L-engine, now there are three.

L-engine crank and bore combinations:83mm stroke (for 2.0 & 1.8L - replaces 77mm crank from F-engine)

94mm stroke (unchanged from 2.2L F-engine)

100mm stroke (new for 2.5L L5)

Standard bore for the L-engine is now 87.5mm, instead of 86mm from F-engine. For the smallest 1.8L, the same 83mm crank as the 2.0L is used, but bore reduced to 83mm as well (square 83x83mm). The 1.8L "MZR" is used overseas for Mazda6, 3 and Ford "Duratec HE".

For comparison, the F-engine had 3 cranks, and 2 bore sizes 86mm being standard bore, however the smaller bore size (83mm) was the rarest:

77mm stroke (86x77mm for 1.8L, 83x77mm for the rare 1.6L)

86mm stroke (86x86mm FE 2.0 was square )

94mm stroke (used for 2.2L F2 and carried over to the L-engine)

So now with a little bit of history, in the early 2000's it was published that Ford had indeed trusted Mazda for a new global 4cylinder for Ford to use. (Mazda's own engines have always been their "global" engine, so no need to change anything on their end). Ford attempted a DOHC 4 cylinder with their ZETEC, being loosely based on Mazda's 1.8L BP, but that engine was short lived. The F-engine was produced from 1983 to the mid-late 90's, where Mazda replaced it with an odd FS/FP 2.0L/1.8L for the Protege generation (was more like a stretched out BP, than close to anything of the real F-engine family). That engine was produced for about ~5yrs, before they went back to a large bore spacing engine like the L- & F-.

"But there are parts on the Mazda and Ford engines that says FoMoCo on it, so you're lying"

Indeed there are, but I'm not even close to lying. This is where the OEM agreements take place. Mazda accepted Ford's offer of helping them save some money on the bread and butter parts like plugs, throttle bodies, dipsticks- you know the [censored] little costs on the little knick knack details. Ford offered these everso discreetly labelled items, you know, as part of an exchange for being able to cast a Mazda engine and use it in over half of their entire lineup. That seems a little more than fair. But, Ford also knows the psychology value in that as well. But I digress.

Now, I realise this is far more info than anyone could have cared for, but I think the story is very good start to at least know the heritage. There is far too much speculation and rough estimates out there, even from journalists in internetsworld that people are stating as fact.

Nick, you've got a good engine. If you have a sensor sticking out of the valve cover on the chain side, you've for VVT. Oh, and you've got nothing to worry about!

--- I would also add Ford opted to drop the Mazda's VVT in favor of there own to be released later (when?) varible valve timming.

-- also mazda use 3wire coil on plug (ignitors built in? I hope) compared to 2wire COP's (seperate ignitor needed).

The new Ford Duratec 2.3L (23E) engine generates 144 horsepower - 10 percent more than today's 2.0-liter Zetec engine - with SULEV emissions. It is due to be upgraded with even more power to 150 horsepower for the 2005 model year, but will lose the PZEV emissions equipment. The PZEV engine will be downsize to a 2.0L displacement.

The new engine is standard equipment in five states and will be available in all the other states, but is reported not to be available in Canada.

Clean, fuel-efficient engine is a product of Ford's "revolution under the hood" that will see more than 1.5 million engines built around the globe from the same in-line four-cylinder (I-4) architecture.

Ford's new Duratec 23E engine, first introduced in the 2003œ Ford Focus PZEV (Partial Zero Emissions Vehicle) in California, New York and Massachusetts and now available nationwide, is both powerful - producing 151 horsepower at 5,750 rpm and 154 pounds-feet of torque at 4,250 rpm - and exceptionally clean.The engine helps Focus meet California's Super Ultra-low Emissions Vehicle (SULEV) standard, which allows vehicles to emit only one pound of smog-forming pollution over 15,000 miles of driving. That's good enough to earn the car a perfect "10" on the U.S. Environmental Protection Agency's Guide to Green Cars. The car also has zero fuel system evaporative emissions. EPA estimated fuel economy is 25 mpg city and 33 mpg highway with the standard five-speed manual transmission and 24 mpg city and 30 mpg highway with the optional four-speed automatic.

"The Focus PZEV and the Duratec 23E are technological breakthroughs that deliver real-world environmental benefits without asking consumers to make a single compromise in performance, driving range, refinement or practicality," said John Sidelko, Focus chief engineer. All 2.3-liter Focus models in 2004 are identical to the Focus PZEV. They share the same emissions hardware, fuel system components and powertrain calibration. However, the emissions are slightly less clean outside of California because of that state's unique fuel formulations.

Power, Refinement and Low EmissionsThe new engine achieves its impressive level of performance, refinement and low emissions through careful design of the engine block and cylinder heads, air and fuel intake systems, powertrain controls, combustion chambers and exhaust system. The Duratec 23E cylinder block is a precision aluminum casting with a deep skirt that extends well below the crankshaft center line to improve bending stiffness. A separate cast aluminum alloy ladder frame carries the lower bearing shells. This casting is secured by 10 bolts, one on each side of the bearing. Dry, cast-iron cylinder bore liners are cast into the block. A structural ribbed aluminum oil plan and cast alloy front cover further stiffen the block and reduce noise transmission.The extensive use of aluminum components and direct mounting of accessories to the engine block helps to reduce the total installed weight of the engine by 40 pounds, or 12 percent, compared with the Ford 2.0-liter Zetec I-4 engine.

Brad

- DPDISXR4Ti

- Site Admin

- Posts: 14831

- Joined: Wed Jan 08, 2003 11:40 pm

- Location: New York

Re: Duratec / Mazda L-Series MZR I4 2.5 Swap

Part 2 of cut & paste...

Cylinder Head and Valve Train

The dual overhead cam (DOHC), four-valve-per cylinder head design uses direct-acting mechanical bucket tappets and an aluminum alloy "high flow" cylinder head with press-fit valve seats that help to improve long-term sealing.Valves and tappets are individually graded for consistency. This assures that proper valve clearances are maintained over the engine's life. Lobes on the chain-driven camshafts are chilled during manufacture to harden them. These actions help eliminate the need for valve adjustments throughout a useful life of 150,000 miles. Each cam runs in five cam bearings, for smooth and quiet operation.Intake valve diameters are 35 millimeters, with 30-millimeter exhaust valves. They are mounted at an included angle of 29 degrees to each other in an asymmetric arrangement - the intake valves are 19 degrees from vertical and the exhaust valves are 10 degrees from vertical. This allows the spark plugs to be mounted near the center of the "pent roof" combustion chamber, a design that promotes circular flame propagation and improves fuel economy, especially under partial load.The camshafts run directly in the aluminum cylinder head and are driven by a "silent" chain for quieter operation. A spring arm maintains proper tension and a hydraulically-activated composite damper controls chain movement. The camshaft cover is made of cast aluminum alloy to contain valve train noise and assure warp-free sealing for life.In addition to designing a durable and quiet-running engine, engineers worked to make engine components as fuel-efficient and lightweight as possible. A good example of this is the new piston, ring and connecting rod assembly, which provides about 15 percent weight advantage compared with other modern engines. Other benefits include superior NVH, lower friction (or parasitic losses) and a free-revving engine characteristic.The electronic distributor-less coil-on-plug ignition system includes a cylinder knock-control system that continuously adapts the engine's operating parameters to optimize performance and economy.To enhance fuel efficiency, the engine uses 5W20 SAE (ILSAC GF-3) grade oil for reduced resistance to flow, and operates at a relatively low idle speed of 700 rpm. Maximum engine speed is 7,000 rpm.

New Intake and Exhaust Manifolds

The computer-designed intake manifold is a prime example of the attention to detail that went into the new engine. It is fully symmetrical, lightweight and made of friction-welded plastic to reduce flow friction and stay cooler than cast metal. This design allowed engineers to "sculpt" the sound of the 16-valve engines to be sporty yet refined.Within each of the manifold's four runners is a butterfly valve that restricts the air passage at low speed. This improves low-speed efficiency by inducing "tumble" or turbulence to accelerate the flow of the air/fuel mixture into the combustion chambers. At higher speeds, the butterfly valves open fully to meet the engine's requirement for more airflow.The intake system also features a new, solid-state temperature and pressure sensor, which makes more precise air mass calculations possible. These are constantly relayed to the electronic powertrain control module for efficient engine operation.The powertrain control module also controls a new electronic exhaust gas recirculation (EGR) system that precisely meters the addition of burned exhaust gases to the intake charge. The extra mass of this inert gas in the intake charge acts as a heat sink to reduce combustion temperatures, which in turn helps reduce the engine's nitrogen oxide emissions.The rear-facing, four-into-one exhaust manifold is formed of tubular steel which heats up faster than a conventional cast-iron unit. The catalysts are mounted very close to the manifold, so they heat to operating temperature quickly to reduce cold-start emissions. The catalysts themselves are a high density design that has more surface area than conventional designs to help reduce tailpipe emissions.

Fuel System

A new four-hole fuel injector design delivers a highly atomized-spray pattern directly toward the twin inlet ports of each cylinder for more spray penetration, better atomization and less cylinder wall wetting than a single-hole injector. This in turn translates into good drivability and lower emissions. Sequential electronic fuel injection control injects precisely measured quantities of fuel into each cylinder individually at the optimum point in each combustion cycle.To help eliminate evaporative emissions, engineers designed a unique air intake system that includes a carbon trap to collect vapors from any residual fuel left in the intake manifold at engine shut off. Other features that help eliminate evaporative emissions are a stainless steel tank, along with upgraded stainless steel fuel lines and connectors.

Wide Range of Engines and Applications

The new Duratec I-4 family is built around a highly flexible architecture that can meet a wide range of vehicle needs around the world. More than 100 variations are possible, including designs optimized for fuel economy, low emissions, sporty performance or torque.Ford eventually expects to build more than 1.5 million of these engines annually in displacements of 1.8- 2.0- and 2.3-liters in various vehicles. This would account for 20 percent of Ford's annual world-wide production of 7 million engines."There's a revolution going on under the hood at Ford," said Dave Szczupak, vice president, Powertrain Operations, Ford Motor Company. "We are introducing an unprecedented number of new powertrains between now and the end of the decade. The things we are doing today will assure that we continue to deliver great powertrains and great vehicles to our customers well into the future. "The new engine family also is leading the way in modern, cost-efficient manufacturing. Four plants on three continents will build Duratec I-4s, and all will benefit from the efficiencies and quality improvements offered by flexible manufacturing techniques.

=====================================

Displacement 2.3L

No. of cylinders 4

Bore/stroke 87.5/94.0

Firing order 1-3-4-2

Oil pressure (hot @ 2,000 rpm) 29-39 psi 200-268 kPa

Belt tension Refer to Section 303-05.

Oil capacity 4.1 qts. + 0.4 qt. with filter

Cylinder Block

Cylinder bore diameter 87.5-87.53 mm (3.444-3.445 in.)

Cylinder bore maximum out-of-round 0.008 mm (0.0003 in.)

Main bearing bore diameter 57.020-57.038 mm (2.244-2.245 in.)

Head gasket surface flatness 0.1 mm/general 0.05 mm/200 x 200 (0.004 in./general) (0.0019 in./7.87 x 7.87)

Piston

Diameter (1) 87.5-87.51 mm (3.444-3.445 in.)

Diameter (2) 87.51-87.52 mm (3.4452-3.4456 in.)

Diameter (3) 87.52-87.53 mm (3.444-3.446 in.)

Piston-to-bore clearance 0.025-0.045 mm (0.0009-0.0017 in.)

Ring groove width — top 1.203-1.205 mm (0.0473-0.0474 in.)

Ring groove width — 2nd 1.17-1.19 mm (0.0.460-0.0468 in.)

Ring groove width — oil 2.501-2.503 mm (0.0984-0.0985 in.)

Piston skirt coating thickness 0.008-0.020 mm (0.0003-0.0007 in.)

Piston Pin

Diameter 20.995-21.0 mm (0.8266-0.8268 in.)

Length 59.6-60.4 mm (2.346-2.377 in.)

Piston-to-pin clearance 0.008-0.016 mm (0.0003-0.0006 in.)

Pin-to-rod clearance Press fit

Cylinder Head

Valve lift @ zero lash (exhaust) 7.4 mm

Valve lift @ zero lash (intake) 7.9 mm

Valve guide diameter 5.509-5.539 mm (0.216-0.218 in.)

Valve seat width — intake/exhaust 0.99-1.84 mm (0.038-0.072 in.)

Valve seat angle 45 degrees

Valve seat runout 0.075 mm (0.0029 in.)

Valve lash adjuster bore diameter 31.00-31.03 mm (1.220-1.221 in.)

Cam bore diameter 25.015-25.040 mm (0.984-0.985 in.)

Valve

Valve head diameter — intake 34.85-35.15 mm (1.372-1.383 in.)

Valve head diameter — exhaust 29.85-30.15 mm (1.175-1.187 in.)

Valve stem diameter — intake 5.470-5.485 mm (0.2153-0.2159 in.)

Valve stem diameter — exhaust 5.465-5.480 mm (0.2151-0.2157 in.)

Valve stem-to-guide clearance — intake 0.0027 mm (0.0001 in.)

Valve stem-to-guide clearance — exhaust 0.0029 mm (0.00011 in.)

Valve face runout 0.05 mm (0.001 in.)

Valve face angle 45 degrees

Valve Spring — Compression Pressure

Intake and exhaust (installed) 38.667 lbs.

Intake (valve open) 8.9 mm (0.35 in) of lift 97.032 lbs.

Exhaust (valve open) 7.4 mm of lift 93.338 lbs.

Free length 44.92 mm (1.768 in.)

Assembled height 37.9 mm (1.492 in.)

Crankshaft

Main bearing journal diameter 51.980-52.000 mm (2.046-2.047 in.)

Production repair 51.730-51.750 mm (2.036-2.037 in.)

Main bearing clearance 0.019-0.035 mm (0.0007-0.0013 in.)

Connecting rod journal diameter 49.980-50.000 mm (1.967-1.968 in.)

Production repair 49.730-49.750 mm (1.957-1.958 in.)

End play 0.22-0.43 mm (0.008-0.016 in.)

Rings

Width — top 1.17-1.185 mm (0.0460-0.0466 in.)

Width — 2nd 1.197-1.199 mm (0.0471-0.0472 in.)

Width — oil 2.38-2.45 mm (0.093-0.096 in.)

Ring gap (in bore) — top 0.16-0.31 mm (0.006-0.012 in.)

Ring gap (in bore) — 2nd 0.33-0.48 mm (0.012-0.018 in.)

Ring gap (in bore) — oil 0.2-0.7 mm (0.007-0.027 in.)

Valve Tappet

Diameter 30.97-30.98 mm (1.2192-1.2196 in.)

Tappet-to-valve clearance — intake 0.22- 0.28 mm (0.008-0.011 in.)

Tappet-to-valve clearance — exhaust 0.27-0.33 mm (0.010-0.013 in.)

Tappet-to-bore clearance 0.02-0.06 mm (0.0007-0.0023 in.)

Camshaft

Lobe lift — intake 8.24999 mm (0.324 in.)

Lobe lift — exhaust 7.80007 mm (0.307 in.)

Runout (1)a 0.03 mm (0.001 in.)

Thrust clearance 0.09-0.24 mm (0.003-0.009 in.)

Journal diameter 24.96-24.98 mm (0.982-0.983 in.)

Journal-to-bore clearance 0.035-0.080 mm (0.001-0.003 in.)

Connecting Rod

Bearing clearance 0.027-0.052 (0.001-0.002 in.)

Bearing thickness 1.496-1.520 mm (0.058-0.059 in.)

Crank bore diameter 53.025-53.045 mm (2.087-2.088 in.)

Pin bore diameter 20.965-20.985 mm (0.825-0.826 in.)

Length (center to center) 154.8 mm (6.094 in.)

Side clearance 1.95-3.05 mm (0.076-0.120 in.)

Axial clearance 0.14-0.36 mm (0.005-0.014 in.)

a No. 3 Journal — Supported by No. 1 and No. 5 journals.

General Specifications Item Specification

Metal Surface Cleaner F4AZ-19A536-RA WSE-M5B392-A

Silicone Gasket and Sealant F7AZ-19554-EA WSE-M4G323-A4

Super Premium SAE 5W-20 Engine Oil XO-5W20-QSP WSS-M2C153-H

MERPOL® O-Ring Seal Lubricant ESE-M99B144-B

Torque Specifications Description Nm lb-ft lb-in

Camshaft bearing capsa — — —

Coolant outlet connection bolts 10 — 89

Oil pan boltsa — — —

Oil pump-to-engine block bolts 25 18 —

Cylinder head boltsa — — —

Intake manifold bolts 18 13 —

Flywheel bolta — — —

Crankshaft pulley bolta — — —

Crankshaft position sensora — — —

Crankshaft oil seal retainera — — —

A/C compressor mounting bolts 25 18 —

Oil pump sprocket bolt 25 18 —

Knock sensor 20 15 —

Engine plug bolt 20 15 —

Rear engine mounting nut 133 98 —

Front engine mounting nuts 80 59

Motor mount bracket bolts 48 35

Engine roll-restrictor bolts 48 35

Engine-to-bellhousing bolts 48 35 —

Torque converter-to-flywheel nuts 35 26 —

Starter motor mounting bolts 25 18 —

Power steering press line tube nut 20 15 —

Powertrain control module (PCM) wiring connector 6 — 53

Coolant pump bolts 10 — 89

Engine front cover boltsa — — —

Camshaft sprocket bolt 72 53 —

Valve cover bolts 10 — 89

Engine lifting eye bolts 45 33 —

Exhaust gas recirculation (EGR) valve assembly bolts 25 18 —

Generator mounting bolts 25 18 —

Thermostat assembly bolts 10 — 89

Oil pump screen and cover assembly 10 — 89

Exhaust manifold studs 17 13 —

Exhaust manifold-to-cylinder head nuts 54 40 —

Coolant pump pulley bolts 25 18 —

Crankshaft position (CKP) sensor boltsa — — —

Generator A/C mounting bracket bolts 48 35 —

Power steering pump mounting bolts 25 18 —

Engine ground cable-to-cylinder head bolt 10 — 89

Oil level indicator tube bolt 10 — 89

Engine wire harness bulkhead connector bolt 10 — 89

Engine body ground bolt 10 — 89

Engine harness ground PCM connector nut 10 — 89

Accelerator control splash shield 8 — 71

Oil pressure sensor 15 11 —

A/C manifold tube bolt 20 15 —

Exhaust manifold-to-exhaust inlet pipe nuts 40 30 —

Transmission tubes bracket bolt 28 21 —

Oil drain plug 28 21 —

Oil pump chain tensioner bolts 10 — 89

Oil pump chain guide bolts 10 — 89

Timing chain guide bolts 10 — 89

Timing chain tensioner bolts 10 — 89

Crankcase ventilation cover assembly bolts 10 — 89

Oil filter adapter bolts 25 18 —

Coolant outlet (front) connector bolts 25 18 —

Air cleaner outlet tube clamps 10 — 89

Accelerator cable bracket 10 — 89

Manifold absolute pressure (MAP) sensor retainer nut 10 — 89

Coil-on-plug retaining bolt 10 — 89

Engine timing plug bolt 20 15 —

Battery tray bolts 12 — 9

Power steering tube bracket nut 13 10 —

Coolant bypass bolt 10 — 89

Belt tensioner bolt 50 37 —

Oil filter cup 33 24 —

Oil pan-to-bellhousing boltsa — — —

Heated oxygen sensor (HO2S) and catalyst monitor sensor wire connector bracket nuts 25 18 —

Bellhousing-to-engine bolts 48 35 —

Bellhousing-to-engine stud bolt 48 35 —

Bellhousing-to-oil pan boltsa — — —

Engine-to-bellhousing stud bolt 48 35 —

Engine front cover-to-oil pan boltsa — — —

Rear main seal mounting plate bolts 10 — 89

Camshaft position (CMP) sensor bolt 7 — 62

Cylinder head temperature (CHT) sensor 12 9 —

Spark plug 15 11 —

Fuel injection supply manifold bolt 18 13 —

Engine vent cover bolt 10 — 89

Pressure plate bolts 32 24

Cylinder Head and Valve Train

The dual overhead cam (DOHC), four-valve-per cylinder head design uses direct-acting mechanical bucket tappets and an aluminum alloy "high flow" cylinder head with press-fit valve seats that help to improve long-term sealing.Valves and tappets are individually graded for consistency. This assures that proper valve clearances are maintained over the engine's life. Lobes on the chain-driven camshafts are chilled during manufacture to harden them. These actions help eliminate the need for valve adjustments throughout a useful life of 150,000 miles. Each cam runs in five cam bearings, for smooth and quiet operation.Intake valve diameters are 35 millimeters, with 30-millimeter exhaust valves. They are mounted at an included angle of 29 degrees to each other in an asymmetric arrangement - the intake valves are 19 degrees from vertical and the exhaust valves are 10 degrees from vertical. This allows the spark plugs to be mounted near the center of the "pent roof" combustion chamber, a design that promotes circular flame propagation and improves fuel economy, especially under partial load.The camshafts run directly in the aluminum cylinder head and are driven by a "silent" chain for quieter operation. A spring arm maintains proper tension and a hydraulically-activated composite damper controls chain movement. The camshaft cover is made of cast aluminum alloy to contain valve train noise and assure warp-free sealing for life.In addition to designing a durable and quiet-running engine, engineers worked to make engine components as fuel-efficient and lightweight as possible. A good example of this is the new piston, ring and connecting rod assembly, which provides about 15 percent weight advantage compared with other modern engines. Other benefits include superior NVH, lower friction (or parasitic losses) and a free-revving engine characteristic.The electronic distributor-less coil-on-plug ignition system includes a cylinder knock-control system that continuously adapts the engine's operating parameters to optimize performance and economy.To enhance fuel efficiency, the engine uses 5W20 SAE (ILSAC GF-3) grade oil for reduced resistance to flow, and operates at a relatively low idle speed of 700 rpm. Maximum engine speed is 7,000 rpm.

New Intake and Exhaust Manifolds

The computer-designed intake manifold is a prime example of the attention to detail that went into the new engine. It is fully symmetrical, lightweight and made of friction-welded plastic to reduce flow friction and stay cooler than cast metal. This design allowed engineers to "sculpt" the sound of the 16-valve engines to be sporty yet refined.Within each of the manifold's four runners is a butterfly valve that restricts the air passage at low speed. This improves low-speed efficiency by inducing "tumble" or turbulence to accelerate the flow of the air/fuel mixture into the combustion chambers. At higher speeds, the butterfly valves open fully to meet the engine's requirement for more airflow.The intake system also features a new, solid-state temperature and pressure sensor, which makes more precise air mass calculations possible. These are constantly relayed to the electronic powertrain control module for efficient engine operation.The powertrain control module also controls a new electronic exhaust gas recirculation (EGR) system that precisely meters the addition of burned exhaust gases to the intake charge. The extra mass of this inert gas in the intake charge acts as a heat sink to reduce combustion temperatures, which in turn helps reduce the engine's nitrogen oxide emissions.The rear-facing, four-into-one exhaust manifold is formed of tubular steel which heats up faster than a conventional cast-iron unit. The catalysts are mounted very close to the manifold, so they heat to operating temperature quickly to reduce cold-start emissions. The catalysts themselves are a high density design that has more surface area than conventional designs to help reduce tailpipe emissions.

Fuel System

A new four-hole fuel injector design delivers a highly atomized-spray pattern directly toward the twin inlet ports of each cylinder for more spray penetration, better atomization and less cylinder wall wetting than a single-hole injector. This in turn translates into good drivability and lower emissions. Sequential electronic fuel injection control injects precisely measured quantities of fuel into each cylinder individually at the optimum point in each combustion cycle.To help eliminate evaporative emissions, engineers designed a unique air intake system that includes a carbon trap to collect vapors from any residual fuel left in the intake manifold at engine shut off. Other features that help eliminate evaporative emissions are a stainless steel tank, along with upgraded stainless steel fuel lines and connectors.

Wide Range of Engines and Applications

The new Duratec I-4 family is built around a highly flexible architecture that can meet a wide range of vehicle needs around the world. More than 100 variations are possible, including designs optimized for fuel economy, low emissions, sporty performance or torque.Ford eventually expects to build more than 1.5 million of these engines annually in displacements of 1.8- 2.0- and 2.3-liters in various vehicles. This would account for 20 percent of Ford's annual world-wide production of 7 million engines."There's a revolution going on under the hood at Ford," said Dave Szczupak, vice president, Powertrain Operations, Ford Motor Company. "We are introducing an unprecedented number of new powertrains between now and the end of the decade. The things we are doing today will assure that we continue to deliver great powertrains and great vehicles to our customers well into the future. "The new engine family also is leading the way in modern, cost-efficient manufacturing. Four plants on three continents will build Duratec I-4s, and all will benefit from the efficiencies and quality improvements offered by flexible manufacturing techniques.

=====================================

Displacement 2.3L

No. of cylinders 4

Bore/stroke 87.5/94.0

Firing order 1-3-4-2

Oil pressure (hot @ 2,000 rpm) 29-39 psi 200-268 kPa

Belt tension Refer to Section 303-05.

Oil capacity 4.1 qts. + 0.4 qt. with filter

Cylinder Block

Cylinder bore diameter 87.5-87.53 mm (3.444-3.445 in.)

Cylinder bore maximum out-of-round 0.008 mm (0.0003 in.)

Main bearing bore diameter 57.020-57.038 mm (2.244-2.245 in.)

Head gasket surface flatness 0.1 mm/general 0.05 mm/200 x 200 (0.004 in./general) (0.0019 in./7.87 x 7.87)

Piston

Diameter (1) 87.5-87.51 mm (3.444-3.445 in.)

Diameter (2) 87.51-87.52 mm (3.4452-3.4456 in.)

Diameter (3) 87.52-87.53 mm (3.444-3.446 in.)

Piston-to-bore clearance 0.025-0.045 mm (0.0009-0.0017 in.)

Ring groove width — top 1.203-1.205 mm (0.0473-0.0474 in.)

Ring groove width — 2nd 1.17-1.19 mm (0.0.460-0.0468 in.)

Ring groove width — oil 2.501-2.503 mm (0.0984-0.0985 in.)

Piston skirt coating thickness 0.008-0.020 mm (0.0003-0.0007 in.)

Piston Pin

Diameter 20.995-21.0 mm (0.8266-0.8268 in.)

Length 59.6-60.4 mm (2.346-2.377 in.)

Piston-to-pin clearance 0.008-0.016 mm (0.0003-0.0006 in.)

Pin-to-rod clearance Press fit

Cylinder Head

Valve lift @ zero lash (exhaust) 7.4 mm

Valve lift @ zero lash (intake) 7.9 mm

Valve guide diameter 5.509-5.539 mm (0.216-0.218 in.)

Valve seat width — intake/exhaust 0.99-1.84 mm (0.038-0.072 in.)

Valve seat angle 45 degrees

Valve seat runout 0.075 mm (0.0029 in.)

Valve lash adjuster bore diameter 31.00-31.03 mm (1.220-1.221 in.)

Cam bore diameter 25.015-25.040 mm (0.984-0.985 in.)

Valve

Valve head diameter — intake 34.85-35.15 mm (1.372-1.383 in.)

Valve head diameter — exhaust 29.85-30.15 mm (1.175-1.187 in.)

Valve stem diameter — intake 5.470-5.485 mm (0.2153-0.2159 in.)

Valve stem diameter — exhaust 5.465-5.480 mm (0.2151-0.2157 in.)

Valve stem-to-guide clearance — intake 0.0027 mm (0.0001 in.)

Valve stem-to-guide clearance — exhaust 0.0029 mm (0.00011 in.)

Valve face runout 0.05 mm (0.001 in.)

Valve face angle 45 degrees

Valve Spring — Compression Pressure

Intake and exhaust (installed) 38.667 lbs.

Intake (valve open) 8.9 mm (0.35 in) of lift 97.032 lbs.

Exhaust (valve open) 7.4 mm of lift 93.338 lbs.

Free length 44.92 mm (1.768 in.)

Assembled height 37.9 mm (1.492 in.)

Crankshaft

Main bearing journal diameter 51.980-52.000 mm (2.046-2.047 in.)

Production repair 51.730-51.750 mm (2.036-2.037 in.)

Main bearing clearance 0.019-0.035 mm (0.0007-0.0013 in.)

Connecting rod journal diameter 49.980-50.000 mm (1.967-1.968 in.)

Production repair 49.730-49.750 mm (1.957-1.958 in.)

End play 0.22-0.43 mm (0.008-0.016 in.)

Rings

Width — top 1.17-1.185 mm (0.0460-0.0466 in.)

Width — 2nd 1.197-1.199 mm (0.0471-0.0472 in.)

Width — oil 2.38-2.45 mm (0.093-0.096 in.)

Ring gap (in bore) — top 0.16-0.31 mm (0.006-0.012 in.)

Ring gap (in bore) — 2nd 0.33-0.48 mm (0.012-0.018 in.)

Ring gap (in bore) — oil 0.2-0.7 mm (0.007-0.027 in.)

Valve Tappet

Diameter 30.97-30.98 mm (1.2192-1.2196 in.)

Tappet-to-valve clearance — intake 0.22- 0.28 mm (0.008-0.011 in.)

Tappet-to-valve clearance — exhaust 0.27-0.33 mm (0.010-0.013 in.)

Tappet-to-bore clearance 0.02-0.06 mm (0.0007-0.0023 in.)

Camshaft

Lobe lift — intake 8.24999 mm (0.324 in.)

Lobe lift — exhaust 7.80007 mm (0.307 in.)

Runout (1)a 0.03 mm (0.001 in.)

Thrust clearance 0.09-0.24 mm (0.003-0.009 in.)

Journal diameter 24.96-24.98 mm (0.982-0.983 in.)

Journal-to-bore clearance 0.035-0.080 mm (0.001-0.003 in.)

Connecting Rod

Bearing clearance 0.027-0.052 (0.001-0.002 in.)

Bearing thickness 1.496-1.520 mm (0.058-0.059 in.)

Crank bore diameter 53.025-53.045 mm (2.087-2.088 in.)

Pin bore diameter 20.965-20.985 mm (0.825-0.826 in.)

Length (center to center) 154.8 mm (6.094 in.)

Side clearance 1.95-3.05 mm (0.076-0.120 in.)

Axial clearance 0.14-0.36 mm (0.005-0.014 in.)

a No. 3 Journal — Supported by No. 1 and No. 5 journals.

General Specifications Item Specification

Metal Surface Cleaner F4AZ-19A536-RA WSE-M5B392-A

Silicone Gasket and Sealant F7AZ-19554-EA WSE-M4G323-A4

Super Premium SAE 5W-20 Engine Oil XO-5W20-QSP WSS-M2C153-H

MERPOL® O-Ring Seal Lubricant ESE-M99B144-B

Torque Specifications Description Nm lb-ft lb-in

Camshaft bearing capsa — — —

Coolant outlet connection bolts 10 — 89

Oil pan boltsa — — —

Oil pump-to-engine block bolts 25 18 —

Cylinder head boltsa — — —

Intake manifold bolts 18 13 —

Flywheel bolta — — —

Crankshaft pulley bolta — — —

Crankshaft position sensora — — —

Crankshaft oil seal retainera — — —

A/C compressor mounting bolts 25 18 —

Oil pump sprocket bolt 25 18 —

Knock sensor 20 15 —

Engine plug bolt 20 15 —

Rear engine mounting nut 133 98 —

Front engine mounting nuts 80 59

Motor mount bracket bolts 48 35

Engine roll-restrictor bolts 48 35

Engine-to-bellhousing bolts 48 35 —

Torque converter-to-flywheel nuts 35 26 —

Starter motor mounting bolts 25 18 —

Power steering press line tube nut 20 15 —

Powertrain control module (PCM) wiring connector 6 — 53

Coolant pump bolts 10 — 89

Engine front cover boltsa — — —

Camshaft sprocket bolt 72 53 —

Valve cover bolts 10 — 89

Engine lifting eye bolts 45 33 —

Exhaust gas recirculation (EGR) valve assembly bolts 25 18 —

Generator mounting bolts 25 18 —

Thermostat assembly bolts 10 — 89

Oil pump screen and cover assembly 10 — 89

Exhaust manifold studs 17 13 —

Exhaust manifold-to-cylinder head nuts 54 40 —

Coolant pump pulley bolts 25 18 —

Crankshaft position (CKP) sensor boltsa — — —

Generator A/C mounting bracket bolts 48 35 —

Power steering pump mounting bolts 25 18 —

Engine ground cable-to-cylinder head bolt 10 — 89

Oil level indicator tube bolt 10 — 89

Engine wire harness bulkhead connector bolt 10 — 89

Engine body ground bolt 10 — 89

Engine harness ground PCM connector nut 10 — 89

Accelerator control splash shield 8 — 71

Oil pressure sensor 15 11 —

A/C manifold tube bolt 20 15 —

Exhaust manifold-to-exhaust inlet pipe nuts 40 30 —

Transmission tubes bracket bolt 28 21 —

Oil drain plug 28 21 —

Oil pump chain tensioner bolts 10 — 89

Oil pump chain guide bolts 10 — 89

Timing chain guide bolts 10 — 89

Timing chain tensioner bolts 10 — 89

Crankcase ventilation cover assembly bolts 10 — 89

Oil filter adapter bolts 25 18 —

Coolant outlet (front) connector bolts 25 18 —

Air cleaner outlet tube clamps 10 — 89

Accelerator cable bracket 10 — 89

Manifold absolute pressure (MAP) sensor retainer nut 10 — 89

Coil-on-plug retaining bolt 10 — 89

Engine timing plug bolt 20 15 —

Battery tray bolts 12 — 9

Power steering tube bracket nut 13 10 —

Coolant bypass bolt 10 — 89

Belt tensioner bolt 50 37 —

Oil filter cup 33 24 —

Oil pan-to-bellhousing boltsa — — —

Heated oxygen sensor (HO2S) and catalyst monitor sensor wire connector bracket nuts 25 18 —

Bellhousing-to-engine bolts 48 35 —

Bellhousing-to-engine stud bolt 48 35 —

Bellhousing-to-oil pan boltsa — — —

Engine-to-bellhousing stud bolt 48 35 —

Engine front cover-to-oil pan boltsa — — —

Rear main seal mounting plate bolts 10 — 89

Camshaft position (CMP) sensor bolt 7 — 62

Cylinder head temperature (CHT) sensor 12 9 —

Spark plug 15 11 —

Fuel injection supply manifold bolt 18 13 —

Engine vent cover bolt 10 — 89

Pressure plate bolts 32 24

Brad

- DPDISXR4Ti

- Site Admin

- Posts: 14831

- Joined: Wed Jan 08, 2003 11:40 pm

- Location: New York

Re: Duratec / Mazda L-Series MZR I4 2.5 Swap

Here's another good cut & paste, pulled from here:

https://www.locostusa.com/forums/viewto ... =4&t=14753

Actually the whole thread ^^^ is great as it involves discussion from many who are putting a Duratec in RWD platform.

What is the Duratec/MZR?

It is the result of the goal to create a common all aluminum 4 cylinder engine used by both Ford (Duratec) and Mazda (MZR) starting in the early/mid-2000s (for the North American market). It is worth noting that Ford has used this name on other engines but those are not what we are talking about. Unless it is an all aluminum 4 cylinder engine measuring 2.0, 2.3, or 2.5L with the exhaust on the right side when mounted north/south, it is not what this thread is about.

The bottom ends are very similar between the Ford and Mazda versions but Mazda typically uses a head with variable valve timing. If you choose to go with the Mazda engine, extra care will be required however you will be rewarded with a little extra power. For comparison's sake, a 2.0 from a Focus barely puts out 140 hp in stock form while a 2.0 from a Miata is in the 160 hp range.

There are also pretty good Wikipedia articles on the Duratec (this outlines the different "Duratecs" including the ones we are not talking about) and the Mazda L series.

What RWD transmission bolts to a Duratec or MZR?

Two and only two production/off-the-shelf RWD transmission options exist; NC Miata or a 2001+ Ranger/B-Series pickup. If you use the Ranger transmission, be sure to get the flywheel, clutch, and starter as they seem to be a unique diameter compared to the rest of the Duratec installations. The NC Miata and Focus 2.0 (at least the 2007 one that I used) had the same diameter flywheel so the NC flywheel mated with the starter.

Several other places like Quads4Rods sell bellhousings to mate other transmissions to the Duratec but it will be more labor intensive and more expensive than the NC or Ranger option. (Edit: Quad4rods no longer exists)

What is needed from the donor vehicles?

Aside from the complete engine with accessories and the transmission, you will need the driveshaft, flywheel, clutch, starter, and slave cylinder to match the transmission. From the engine donor, you will need the engine and chassis wiring harnesses, ECU, the key that matches the ECU (very important as the Ford ECU PATS will not start the engine without it), the PATS antenna located in the steering column near the key, O2 sensors, complete intake/airbox with MAF sensor and throttle cable, fuel pump driver module (FPDM), and the stock fuel pump (the ECU controls fuel pressure electronically so these are a must).

The Ranger ends up being the most economical and practical powertrain donor since everything comes from one vehicle. The NC Miata is a much more expensive donor and mixing and matching engines and transmissions will requiring sourcing parts from multiple vehicles and end up being somewhere between a NC Miata and a Ranger price-wise (I went this route; it is doable but more difficult).

What differs between the different engines?

All engines tend to share the same bottom end but as the displacement increases so does the stroke and the engine height. For instance the 2.3L Duratec is approximately 0.5" taller than the 2.0L so extra clearance is needed.

The compression ratios also vary slightly between engines:

2.0L Duratec and MZR - 10:1

2.3L Duratec (Ranger) - 9.7:1

(See Justin's post below for head flow) Also according to SB Motorsports' website, the 08+ 2.0L heads had higher flow numbers (RF3S4G and RF6S4E casting numbers) compared to the earlier 2.0L engines but these heads were likely not used in the US market.

Donors?

The 2001 Ranger/B-Series were among the first vehicles to use the engine (I believe this was a mid model year change). Otherwise if it is a Ford or Mazda made after 2005 and it has a 2.0, 2.3, or 2.5L four cylinder engine, it is more than likely a what we are talking about. In recent years direct injection, Atkinson cycle (used on hybrid installations), and some other technology has appeared so pay attention when getting an engine from a newer donor.

After Market Support and Common Mods

Cosworth (goes without saying)

Crower - they offer cams and a few other items.

SBD Motorsports - they offer some interesting performance products and have some good information

AT Power (also from the UK) offers fuel rails with 6AN fittings and some good other stuff

Raceline

Eagle Rod - connecting rods

https://www.locostusa.com/forums/viewto ... =4&t=14753

Actually the whole thread ^^^ is great as it involves discussion from many who are putting a Duratec in RWD platform.

What is the Duratec/MZR?

It is the result of the goal to create a common all aluminum 4 cylinder engine used by both Ford (Duratec) and Mazda (MZR) starting in the early/mid-2000s (for the North American market). It is worth noting that Ford has used this name on other engines but those are not what we are talking about. Unless it is an all aluminum 4 cylinder engine measuring 2.0, 2.3, or 2.5L with the exhaust on the right side when mounted north/south, it is not what this thread is about.

The bottom ends are very similar between the Ford and Mazda versions but Mazda typically uses a head with variable valve timing. If you choose to go with the Mazda engine, extra care will be required however you will be rewarded with a little extra power. For comparison's sake, a 2.0 from a Focus barely puts out 140 hp in stock form while a 2.0 from a Miata is in the 160 hp range.

There are also pretty good Wikipedia articles on the Duratec (this outlines the different "Duratecs" including the ones we are not talking about) and the Mazda L series.

What RWD transmission bolts to a Duratec or MZR?

Two and only two production/off-the-shelf RWD transmission options exist; NC Miata or a 2001+ Ranger/B-Series pickup. If you use the Ranger transmission, be sure to get the flywheel, clutch, and starter as they seem to be a unique diameter compared to the rest of the Duratec installations. The NC Miata and Focus 2.0 (at least the 2007 one that I used) had the same diameter flywheel so the NC flywheel mated with the starter.

Several other places like Quads4Rods sell bellhousings to mate other transmissions to the Duratec but it will be more labor intensive and more expensive than the NC or Ranger option. (Edit: Quad4rods no longer exists)

What is needed from the donor vehicles?

Aside from the complete engine with accessories and the transmission, you will need the driveshaft, flywheel, clutch, starter, and slave cylinder to match the transmission. From the engine donor, you will need the engine and chassis wiring harnesses, ECU, the key that matches the ECU (very important as the Ford ECU PATS will not start the engine without it), the PATS antenna located in the steering column near the key, O2 sensors, complete intake/airbox with MAF sensor and throttle cable, fuel pump driver module (FPDM), and the stock fuel pump (the ECU controls fuel pressure electronically so these are a must).

The Ranger ends up being the most economical and practical powertrain donor since everything comes from one vehicle. The NC Miata is a much more expensive donor and mixing and matching engines and transmissions will requiring sourcing parts from multiple vehicles and end up being somewhere between a NC Miata and a Ranger price-wise (I went this route; it is doable but more difficult).

What differs between the different engines?

All engines tend to share the same bottom end but as the displacement increases so does the stroke and the engine height. For instance the 2.3L Duratec is approximately 0.5" taller than the 2.0L so extra clearance is needed.

The compression ratios also vary slightly between engines:

2.0L Duratec and MZR - 10:1

2.3L Duratec (Ranger) - 9.7:1

(See Justin's post below for head flow) Also according to SB Motorsports' website, the 08+ 2.0L heads had higher flow numbers (RF3S4G and RF6S4E casting numbers) compared to the earlier 2.0L engines but these heads were likely not used in the US market.

Donors?

The 2001 Ranger/B-Series were among the first vehicles to use the engine (I believe this was a mid model year change). Otherwise if it is a Ford or Mazda made after 2005 and it has a 2.0, 2.3, or 2.5L four cylinder engine, it is more than likely a what we are talking about. In recent years direct injection, Atkinson cycle (used on hybrid installations), and some other technology has appeared so pay attention when getting an engine from a newer donor.

After Market Support and Common Mods

Cosworth (goes without saying)

Crower - they offer cams and a few other items.

SBD Motorsports - they offer some interesting performance products and have some good information

AT Power (also from the UK) offers fuel rails with 6AN fittings and some good other stuff

Raceline

Eagle Rod - connecting rods

Brad

-

john keefe

- Level 7

- Posts: 1069

- Joined: Sat Sep 02, 2006 1:13 pm

- Location: Campbell, CA

Re: Duratec / Mazda L-Series MZR I4 2.5 Swap

Were there any usable RWD Auto transmission combinations that can be used with the Scorpio? DMV requires the same gearing-and-diff combo that came with the original/donor setup. And, though it'd be nice to convert to a manual, I recall some conversation(s) about CA not recognizing that Scorpios came with 5-speeds?

- DPDISXR4Ti

- Site Admin

- Posts: 14831

- Joined: Wed Jan 08, 2003 11:40 pm

- Location: New York

Re: Duratec / Mazda L-Series MZR I4 2.5 Swap

I would think the Ranger, Miata, or 2015+ Ecoboost Mustang could supply donors.john keefe wrote: ↑Wed Dec 28, 2022 3:21 pm Were there any usable RWD Auto transmission combinations that can be used with the Scorpio?

Brad

Re: Duratec / Mazda L-Series MZR I4 2.5 Swap

Scorpio's did come with a 5speed though, just not many of them. If it is possible to find build information, or someone who has an originally equipped manual trans Scorpio, maybe that could help whoever needs to recognize...john keefe wrote: ↑Wed Dec 28, 2022 3:21 pm Were there any usable RWD Auto transmission combinations that can be used with the Scorpio? DMV requires the same gearing-and-diff combo that came with the original/donor setup. And, though it'd be nice to convert to a manual, I recall some conversation(s) about CA not recognizing that Scorpios came with 5-speeds?

Re: Duratec / Mazda L-Series MZR I4 2.5 Swap

Good info, thanks for posting. This helps a lot...DPDISXR4Ti wrote: ↑Wed Dec 28, 2022 2:21 pm Here's another good cut & paste, pulled from here:

https://www.locostusa.com/forums/viewto ... =4&t=14753

Actually the whole thread ^^^ is great as it involves discussion from many who are putting a Duratec in RWD platform.

-

john keefe

- Level 7

- Posts: 1069

- Joined: Sat Sep 02, 2006 1:13 pm

- Location: Campbell, CA

Re: Duratec / Mazda L-Series MZR I4 2.5 Swap

Thanks. I figured there had to be some RWD Auto combination for the Mustang, just the only thing that came to mind was the Ranger and FWD Fusion. Can't swap in a truck setup to a car, though. From my experience with the Smog Ref, if it ain't in the official book, then according to them it didn't exist... not sure what proof they'd need for a manual Scorpio, or if they'd even accept a third party set of specs. On the other hand, I don't see why they wouldn't allow for a complete swap over as long as all the relevant, required donor parts are in place. I think I'd still lean towards the Lincoln LS setup.DPDISXR4Ti wrote: ↑Wed Dec 28, 2022 10:42 pmI would think the Ranger, Miata, or 2015+ Ecoboost Mustang could supply donors.

Re: Duratec / Mazda L-Series MZR I4 2.5 Swap

Why would the Lincoln LS swap be ok but this not?john keefe wrote: ↑Thu Dec 29, 2022 2:40 pmThanks. I figured there had to be some RWD Auto combination for the Mustang, just the only thing that came to mind was the Ranger and FWD Fusion. Can't swap in a truck setup to a car, though. From my experience with the Smog Ref, if it ain't in the official book, then according to them it didn't exist... not sure what proof they'd need for a manual Scorpio, or if they'd even accept a third party set of specs. On the other hand, I don't see why they wouldn't allow for a complete swap over as long as all the relevant, required donor parts are in place. I think I'd still lean towards the Lincoln LS setup.DPDISXR4Ti wrote: ↑Wed Dec 28, 2022 10:42 pmI would think the Ranger, Miata, or 2015+ Ecoboost Mustang could supply donors.

This should actually be better, it is a current engine available to buy now it a 50 state legal vehicle.

Tell them how much more efficient and clean this would be compared to the 35yr old dirty V6.

-

john keefe

- Level 7

- Posts: 1069

- Joined: Sat Sep 02, 2006 1:13 pm

- Location: Campbell, CA

Re: Duratec / Mazda L-Series MZR I4 2.5 Swap

I liked the TQ profile of the LS duratec, plus its a no brainer to keep the auto that comes with it... ready made to just swap the whole thing in, no adapter(s) needed to make the trans work other than the DS. As a complete package, it'd probably pass the smog ref with fewer headaches.

Which begs the question, how to make these dirty 2.9L more efficient and MPG friendly?

Re: Duratec / Mazda L-Series MZR I4 2.5 Swap

Stick to the roads that run downhill.john keefe wrote: ↑Fri Dec 30, 2022 5:17 pm Which begs the question, how to make these dirty 2.9L more efficient and MPG friendly?

- DPDISXR4Ti

- Site Admin

- Posts: 14831

- Joined: Wed Jan 08, 2003 11:40 pm

- Location: New York

Re: Duratec / Mazda L-Series MZR I4 2.5 Swap

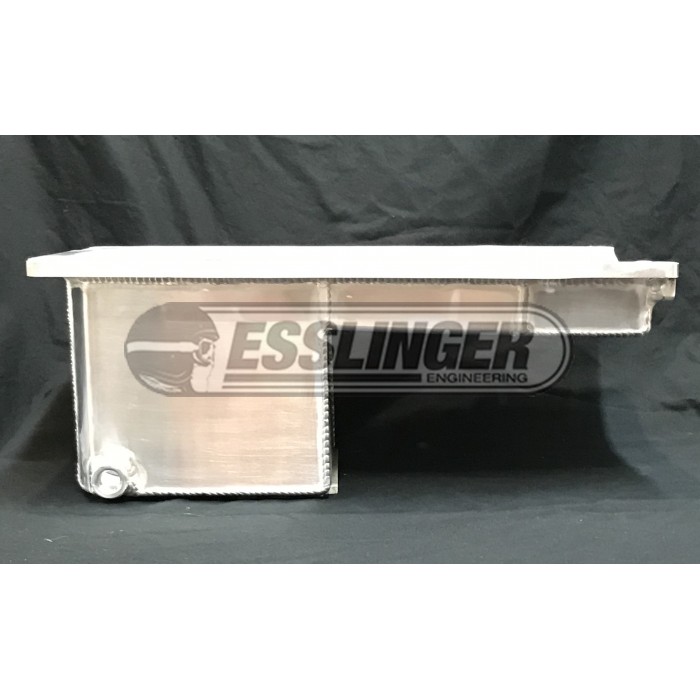

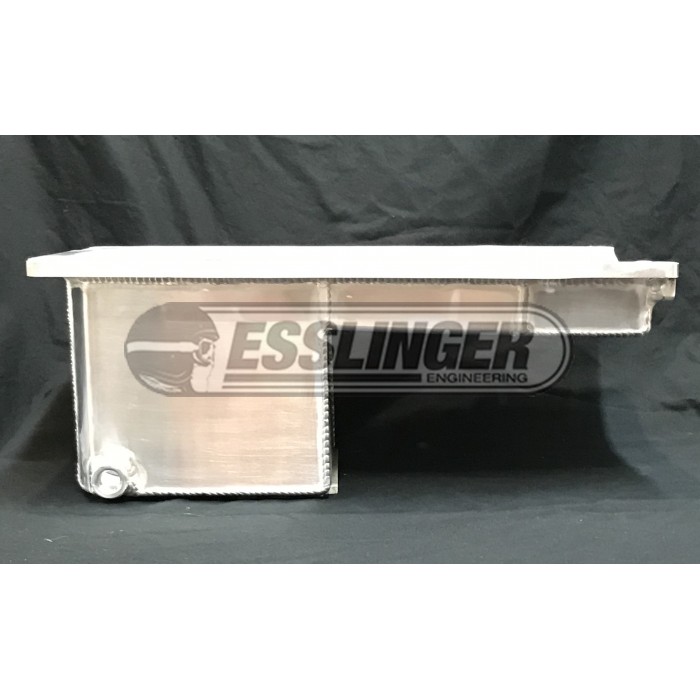

Back on topic, there are a couple options for an oil pan / wet sump for a RWD Duratec swap.

The Ranger pan and pickup *could* be used, but it might conflict with the X-member. The lowest profile factory sump would come from a 2006-2015 NC Miata MX-5 which uses the Duratec 2.0. You would need to delete the balance shaft (2.0 didn't even come with one), and go with the 2.0 oil pump, as is often done on these swaps.

Back to the UK we go, where this kit seems to be widely available. Not cheap, but it does come with everything you need including the custom pickup and dipstick tube. Here too, the 2.0 oil pump is required.

https://www.retroford.co.uk/product/dur ... sump-d007/

Esslinger also makes a custom pan/pickup for $849. It would seem it does clear the 2.5 oil pump, so no need to use the 2.0 pump with this pan. I'm not sure if it clears the factory X-member. Need to check against this data-point supplied by Esslinger... "Sump begins 9-3/8" back from the front of the block"

https://esslingeracing.com/oilpans-4/re ... wap-oilpan

The Ranger pan and pickup *could* be used, but it might conflict with the X-member. The lowest profile factory sump would come from a 2006-2015 NC Miata MX-5 which uses the Duratec 2.0. You would need to delete the balance shaft (2.0 didn't even come with one), and go with the 2.0 oil pump, as is often done on these swaps.

Back to the UK we go, where this kit seems to be widely available. Not cheap, but it does come with everything you need including the custom pickup and dipstick tube. Here too, the 2.0 oil pump is required.

https://www.retroford.co.uk/product/dur ... sump-d007/

Esslinger also makes a custom pan/pickup for $849. It would seem it does clear the 2.5 oil pump, so no need to use the 2.0 pump with this pan. I'm not sure if it clears the factory X-member. Need to check against this data-point supplied by Esslinger... "Sump begins 9-3/8" back from the front of the block"

https://esslingeracing.com/oilpans-4/re ... wap-oilpan

Brad

-

john keefe

- Level 7

- Posts: 1069

- Joined: Sat Sep 02, 2006 1:13 pm

- Location: Campbell, CA

Re: Duratec / Mazda L-Series MZR I4 2.5 Swap

Or, at least the very long downhill grades which give you a chance to coast back up as far as possible up the next hill.my8950 wrote: ↑Fri Dec 30, 2022 7:50 pmStick to the roads that run downhill.john keefe wrote: ↑Fri Dec 30, 2022 5:17 pm Which begs the question, how to make these dirty 2.9L more efficient and MPG friendly?

Sorry Brad, wasn't trying to hijack the thread. Great write-up BTW. You have a ton of patience to type that much in one stretch.

-

Ed Lijewski

- Level 8

- Posts: 8416

- Joined: Thu Sep 04, 2003 5:53 pm

- Location: The Belly of The Beast

Re: Duratec / Mazda L-Series MZR I4 2.5 Swap

[John: he cut-and-pasted.]

Descartes: "Cogito Ergo Sum"

Lijewski: "Sum Ergo Drive-O. Mucho!

Lijewski: "Sum Ergo Drive-O. Mucho!

-

john keefe

- Level 7

- Posts: 1069

- Joined: Sat Sep 02, 2006 1:13 pm

- Location: Campbell, CA

Re: Duratec / Mazda L-Series MZR I4 2.5 Swap

Ha! Well, I would have messed it up, so kudo's anyway.